- From April 1, all of India moves to Bharat Stage IV (BS-IV) vehicular emission norms, already in place in several parts of the country.

- The fuel sector has said it is committed to the move, but sections of the auto sector continue to lobby hard for a relaxation in the deadline, citing the need to liquidate unsold stock with older emissions technology.

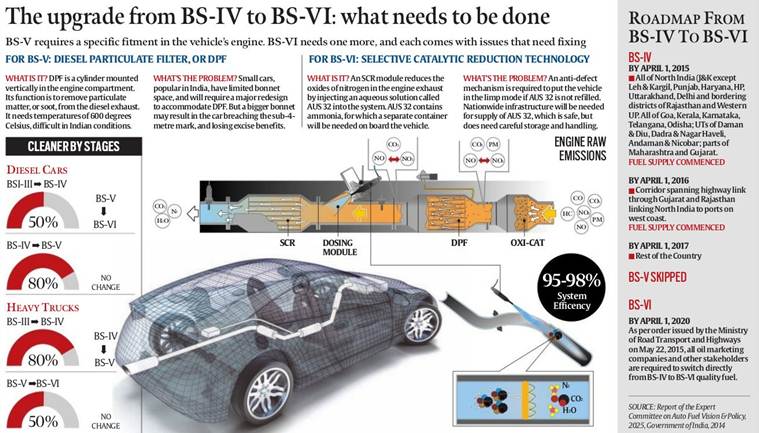

- A bigger bugbear for the sector is the fact that under the auto fuel policy, the intermediate BS-V level is to be skipped, and automakers and fuel suppliers are expected to leapfrog straight to BS-VI norms by April 1, 2020.

- The implementation of the intermediate stage — BS-V standard — was originally scheduled for 2019.

- While this stage has been bypassed, the BS-VI standard, originally proposed to come in by 2024, has been advanced by 4 years — in line with promises India made at the Climate Change Conference in Paris in 2015, and the broad public sentiment against dangerously high levels of air pollution in major Indian cities, led by Delhi.

India’s emissions standards

- The BS — or Bharat Stage — emission standards are norms instituted by the government to regulate the output of air pollutants from internal combustion engine equipment, including motor vehicles.

- India has been following the European (Euro) emission norms, though with a time-lag of five years.

- India introduced emission norms first in 1991, and tightened them in 1996, when most vehicle manufacturers had to incorporate technology upgrades like catalytic converters to cut exhaust emissions.

- Fuel specifications based on environmental considerations were notified first in April 1996 — to be implemented by 2000, and incorporated in BIS 2000 standards.

- Following the landmark Supreme Court order of April 1999, the Centre notified Bharat Stage-I (BIS 2000) and Bharat Stage-II norms, broadly equivalent to Euro I and Euro II respectively. BS-II was for the NCR and other metros; BS-I for the rest of India.

- From April 2005, in line with the Auto Fuel Policy of 2003, BS-III and BS-II fuel quality norms came into existence for 13 major cities, and for the rest of the country respectively.

- From April 2010, BS-IV and BS-III norms were put in place in 13 major cities and the rest of India respectively.

- As per the roadmap in the auto fuel policy, BS-V and BS-VI norms were to be implemented from April 1, 2022, and April 1, 2024, respectively.

- But in November 2015, the Road Transport Ministry issued a draft notification advancing the implementation of BSV norms for new four-wheel vehicle models to April 1, 2019, and for existing models to April 1, 2020.

- The corresponding dates for BS-VI norms were brought forward to April 1, 2021, and April 1, 2022, respectively. The decision to leapfrog to BS-VI from April 1, 2020 effectively skipped BS-V all together.

Drawbacks:

- There are questions about the ability of oil marketing companies to quickly upgrade fuel quality from BS-III and BS-IV standards to BS-VI, which is likely to cost upwards of Rs 40,000 crore.

- More challenging is the task of getting auto firms to make the leap.

- Automakers have said that going to BS-VI directly would leave them with not enough time to design changes in their vehicles, considering that two critical components — diesel particulate filter and selective catalytic reduction module — would have to be adapted to India’s peculiar conditions, where running speeds are much lower than in Europe or the US.

- These challenges are very real — note that the penetration of BS-IV motor spirit (petrol) in the domestic market a full four years after its introduction in the metros, was just about 24%, and that of BS-IV high speed diesel only 16%, according to government data up to end-2014.

- Also, the rollout model of introducing higher grade fuel and vehicles first in the cities has fundamental drawbacks, as was evident in the BS-IV implementation. In the periphery of designated BS-IV cities, BS-III vehicles could be registered; BS-IV vehicles (especially heavy vehicles) were more expensive, and BS-III fuel was cheaper than the BS-IV equivalent. And interstate trucks and buses, the biggest polluters, were forced to stay on with BS-III engines simply because the fuel outside cities did not conform to BS-IV norms.

Need for investments

- The government has been unable to move entirely to BS-IV because refiners have been unable to produce the superior fuel in required quantities.

- Broadly, BS-IV petrol and diesel have 50 parts per million (ppm) of sulphur, as compared to 150 ppm for petrol and 350 ppm for diesel under BS-III standards.

- Oil companies are learnt to have put in Rs 30,000 crore between 2005 and 2010 to upgrade; the auto industry has made investments of a similar size.

- Oil firms will have to invest another about Rs 40,000 crore to upgrade to BS-VI; additional investments by automakers will inevitably raise the prices of vehicles.

Technological requirements

- The auto industry argues that the huge improvements in vehicular technology since 2000 have had little impact in India due to Indian driving, road and ambient conditions.

- The technology that will be used in future BS-VI vehicles, though, will have considerable impact, they claim. BS-V diesel vehicles were to have engine upgrades, particulate filters, lots of sensors, and electronic control.

- Petrols were to have catalyst and electronic control upgrades.

- Industry estimates of required investment to upgrade from BS-IV to BS-V are to the tune of Rs 50,000 crore.

- Vehicles must be fitted with DPF (diesel particulate filter), which has its specific problems in the Indian context.

- Also, DPF would have to be optimised for Indian conditions.

- The technology available in Europe can’t be used directly, claim auto majors.

- Low driving speeds would make it difficult to achieve temperatures of 600 degrees Celsius required to burn the soot in DPF, and equipment manufacturers would have to work with temperatures of 400 degrees.

- Usually, diesel is injected to increase temperatures, but the accumulation of excess fuel in the compartment can cause a fire. The integrity of the vehicle too has to be considered.

- This would require validation tests over 600,000-700,000 km — a process that may take up to 4 years.

- BS-VI vehicles also have to be equipped with an SCR (selective catalytic reduction) module (see graphic) the optimisation and fitment of which too could take an estimated 3-4 years.

- At every stage, the technology is getting more complex.

- To attain the specified super low emissions, all reactions have to be precise, and controlled by microprocessors.

- Since BS-V is to be skipped entirely, both DPF and SCR would need to be fitted together for testing, which, auto firms say, would make it extremely difficult to detect which of the technologies is at fault in case of errors in the system.

Source: Indian Express